Breakthrough in Biomimetic Muscle Technology: Bringing Natural Motion to Robots

Scientists at the University of California, Los Angeles (UCLA) have published a groundbreaking study in Science, unveiling a new high-performance dielectric elastomer material—PHDE—that enables the creation of artificial muscles even stronger and more flexible than biological ones. This breakthrough brings robots one step closer to achieving smooth, lifelike movement.

Traditional artificial muscle materials face a trade-off: acrylics offer high actuation strain but require pre-stretching and lack flexibility; silicones are easier to process but struggle under high stress. UCLA researchers overcame this challenge by innovatively adjusting the cross-linking between polymer chains, creating an improved acrylic-based material.

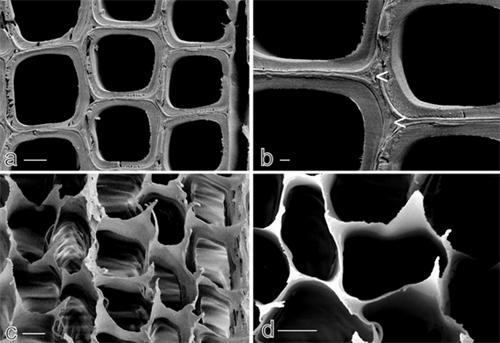

A key to the technology lies in its unique manufacturing process. The team used a “dry” method, slicing thin films with blades and then curing them under ultraviolet light to ensure uniformity across layers. The resulting PHDE film is as thin as a strand of hair—just 35 micrometers thick—but when stacked in multiple layers, it generates impressive force. In experiments, a 4×5-inch film composed of 10 PHDE layers and 20 actuators demonstrated stunning capabilities—it could bend and leap like a spider’s leg and even throw objects 20 times its own weight.

The performance metrics are striking: this artificial muscle generates more power than biological muscle and is 3 to 10 times more flexible. Most notably, it efficiently transforms electrical energy into mechanical motion. As voltage changes, the actuator expands and contracts like a diaphragm, closely mimicking the behavior of real muscle.

This technology could revolutionize the medical field. Imagine surgical robots equipped with such artificial muscles, performing delicate procedures with enhanced precision, greatly improving safety and success rates. In minimally invasive surgeries, soft robotic arms could move as flexibly as human hands while maintaining force control—reducing trauma and speeding up recovery times.

Service robots stand to make a quantum leap as well. Current caregiving robots often move stiffly and have a cold, mechanical appearance. With these new artificial muscles, robots could display natural body language and a softer touch, offering more humanlike care to the elderly and children. They could gently hold an elderly person’s hand or carefully lift an infant—creating more comforting, emotionally resonant interactions.

Industrial manufacturing will also benefit from this breakthrough. Traditional robotic arms often fall short on precision assembly lines when it comes to tasks that demand gentle, flexible handling.Robots equipped with artificial muscles can manipulate objects with humanlike dexterity, precisely controlling force while adapting to irregular shapes.

This innovation marks not only a major advancement in materials science but also signals a new era in robotics. As the technology matures and moves toward commercialization, we may soon see a new generation of robots with more natural movement and intuitive interactions entering daily life. In a sense, these artificial muscles—so lifelike in motion—are beginning to blur the line between machine and life, offering a glimpse into a future of human-machine symbiosis.

Importantly, the implications go beyond robotics. This technology could pave the way for next-generation prosthetics and exoskeletons, restoring near-natural mobility to people with disabilities. In extreme environments such as space exploration, these durable, flexible actuators may play a crucial role. In short, this breakthrough is opening up new possibilities across a wide range of fields.

Recommended for you: