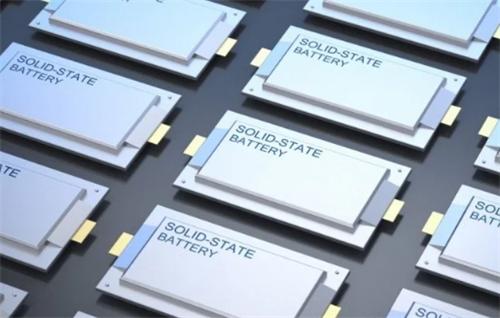

Countdown to mass production of solid-state batteries: Who leads, Toyota or CATL?

The global new energy vehicle (NEV) industry is undergoing a quiet revolution, and at the heart of this transformation is the race to develop and mass-produce solid-state batteries. In this high-stakes technological battle that could define the next decade, the rivalry between Japanese automotive giant Toyota and Chinese battery leader CATL (Contemporary Amperex Technology Co., Limited) stands out. Their choices of technical pathways, production timelines, and commercialization strategies will profoundly shape the direction of the global NEV industry.

Competing Technologies: Sulfide vs. Oxide Electrolytes

The key breakthrough for solid-state batteries lies in the innovation of electrolyte materials. Toyota has opted for the sulfide-based route, which offers an ionic conductivity close to that of conventional liquid electrolytes (around 10⁻² S/cm) and holds the potential for high energy density. Toyota claims its sulfide-based solid-state batteries could power EVs for up to 1,200 kilometers on a single charge—potentially securing a market edge with industry-leading range.However, the sulfide material requires a tightly controlled manufacturing environment—free of moisture and oxygen—and faces interfacial stability challenges. Industry analysts project that the global solid-state battery market could reach $15.07 billion by 2030, driven by increasing demand in electric vehicles, portable electronics, and energy storage systems.

In contrast, CATL has adopted a more flexible composite approach, combining sulfide with polymer electrolytes. By optimizing formulations (such as Li₆PS₅Cl), the company has achieved an energy density of 500 Wh/kg in the lab—significantly higher than the 320 Wh/kg typical of current lithium-ion batteries. CATL’s chairman, Robin Zeng, introduced the “multi-core technology,” which further minimizes interfacial resistance.Its 20Ah prototypes have passed extreme environment tests, suggesting it may be closer to commercialization.

2026: The Year of Mass Production Showdown

Despite following different technological paths, both companies have set 2026 as a pivotal milestone. Toyota plans to begin small-scale trial production that year, aiming for full-scale deployment by 2030. CATL, on the other hand, is executing a three-stage strategy—research, pilot testing, and mass production—and expects to begin equipping vehicles with sulfide solid-state batteries in 2026. SAIC Motor, one of CATL’s major partners, has also set 2026 as its target for launching a new generation of solid-state batteries, boasting 400 Wh/kg energy density and over 820 Wh/L in volumetric energy density, creating a synergistic effect across the supply chain.

This race toward mass production is driven by the NEV industry’s urgent demand for next-generation battery technology. Solid-state batteries, with their superior energy density, fast-charging capability, and enhanced safety, are seen as the solution to current limitations in electric vehicle performance.

Commercialization Challenges: Cost and Supply Chain Hurdles

Behind the promising lab results loom substantial challenges to mass production. Cost is the foremost concern. Toyota estimates its first-generation solid-state battery will cost about $150 per kWh—more than twice that of liquid batteries. While CATL hasn’t released exact figures, the limited availability of key raw materials such as lithium and sulfur could drive up prices.

Supply chain reconfiguration is another major obstacle. Solid-state batteries require entirely new production equipment and packaging processes. Japan, leveraging its strengths in precision manufacturing, has mobilized 27 companies and institutions to invest ¥15 billion in building a solid-state battery ecosystem.

Future Landscape: A Battle of Technology and Strategy

From a technical perspective, Toyota holds a clear advantage in projected driving range, but its slower commercialization pace is a drawback. Experts predict a period of differentiated market competition: in the initial 2026 rollout, both companies are likely to focus on premium vehicles—such as Toyota’s Lexus series and CATL-powered luxury EVs—where “technology premiums” can help offset costs.

In the long run, cost control and technology reliability will be decisive. If CATL can drive costs below $100 per kWh by 2028, it could disrupt the current power battery market. Conversely, if Toyota can resolve interfacial stability issues, it may reclaim dominance through the strong reputation of Japanese engineering. Meanwhile, European automakers like Volkswagen and BMW have adopted a “dual-supplier” strategy, partnering with both Japanese and Chinese firms to hedge against technological uncertainty.

Global Impact: Reshaping the Supply Chain

The countdown to solid-state battery mass production is already reshaping global supply chains. On the materials side, lithium demand is shifting from rapid expansion to more refined utilization. Solid-state batteries’ reliance on lithium metal anodes may trigger a new round of resource competition. On the policy front, China is pushing companies to upgrade through its “dual-credit” system, while Japan is backing its national development with subsidies via the “All-Solid-State Battery Development Project.”

This race toward mass production isn’t just about corporate rivalry—it will define the trajectory of the global NEV industry over the next decade. As 2026 approaches, the world is watching closely: who will break through the bottleneck first? Which technology path will win out? The answers may begin to take shape within the next two years.

Recommended for you: